Driven by tradition and modern technology, we can fulfill your dream with incredible detail and laser precision using a 3D printer

In addition to our decades of tradition, Velmar also relies on the most advanced technologies in jewellery making. That’s why we offer the modelling of customized items using a 3D printer. Our mission is to turn your dreams into reality. If you have an idea for a unique piece of jewelry you want to wear or give to a special someone, we can help. Let us know what you expect from the finished product, and we will come up with a design that meets your desires using high quality materials and technology. Our jewellery is original and made especially for you.

in real time

Using professional software for building models in 3D environment, we will recreate the product as accurately as possible according to your requirements. You will be able to choose from a variety of materials, colours and designs, and receive feedback and an improved model at every stage of development. You will be able to adjust and modify your 3D piece yourself until we achieve the desired result. Our goal is to provide you with a quality and personalized 3D jewelry piece that meets your expectations and needs.

Completing the 3D model is an important step in the process of creating a custom piece of jewelry. Using photorealism, based on the chosen materials and design, you will be able to see a final vision of what your jewelry would look like before it is printed. This technique seeks to mimic the real world – light, shadows, colours, reflections and textures, making the 3D model look very real. But it’s not too late to make final changes to specific details or small improvements. Once the 3D model is completed in its final version, the file is prepared and loaded onto a 3D printer, where the real magic begins!

see the 3D model on site

Your 3D model has been successfully printed and is being prepared for the next step. The highest quality rubber available on the market is used, specially designed for professional jewellery to the finest detail. We will take care of removing the reinforcements and cleaning the model so you get the best quality possible without compromise. If you prefer, you can come in and see the 3D printed model in person before we proceed with the metal casting.

Your 3D model is cast in precious metal and remains the final stage. These final steps are also the most important in the making of your custom jewellery. The careful workmanship, professional mounting of stones and stunning finishing require knowledge, precision and attention. All of these processes are done by hand by our experienced goldsmiths, who work with us to deliver the highest quality product and to ensure its safe and harmonious appearance.

Are you ready to see your dream jewel in its finished version?

Custom jewelry making is an art that blends creativity, craftsmanship, and personal expression. At VELMAR, we specialize in creating bespoke pieces that reflect the unique style and personality of each client. Our custom jewelry making process ensures that every piece is a work of art, crafted with meticulous attention to detail and the finest materials. In this article, we explore the world of custom jewelry, from the intricate process of jewelry making to the personal touch of handmade jewelry.

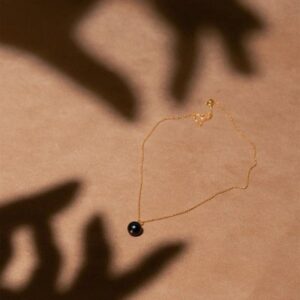

Custom jewelry making is a collaborative process that involves the client and the jeweler working together to create a unique piece. This process begins with a consultation where the client's vision and preferences are discussed. Whether it's a custom engagement ring, a personalized necklace, or a unique bracelet, the goal is to bring the client's dream to life.

The design phase is crucial in custom jewelry making. Our skilled jewelers use advanced software to create detailed sketches and 3D models of the proposed design. This allows the client to visualize the piece and make any adjustments before the actual crafting begins. The use of technology in jewelry making has revolutionized the custom jewelry industry, making it possible to create intricate designs with precision.

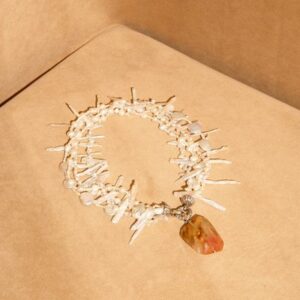

Handmade jewelry is at the core of custom jewelry making. Each piece is crafted by skilled artisans who use traditional techniques to create stunning works of art. The process of handmade jewelry involves several stages, including metalworking, stone setting, and polishing. The result is a unique piece that embodies the artisan's craftsmanship and the client's personal touch.

The appeal of handmade jewelry lies in its uniqueness and quality. Unlike mass-produced pieces, handmade jewelry is crafted with care and attention to detail. Every piece is different, reflecting the individuality of the wearer. At VELMAR, our artisans take pride in their work, ensuring that each piece of handmade jewelry is a masterpiece.

Consultation and Design: The custom jewelry making process begins with a consultation where the client's ideas and preferences are discussed. This is followed by the design phase, where detailed sketches and 3D models are created. The client has the opportunity to review and approve the design before crafting begins.

Material Selection: Choosing the right materials is crucial in custom jewelry making. Whether it's gold, silver, platinum, or a combination of metals, the choice of material affects the final look and feel of the piece. Clients can also select gemstones, such as diamonds, sapphires, or emeralds, to be incorporated into the design.

Crafting the Piece: Once the design is approved and materials are selected, the actual crafting begins. This involves several stages, including metalworking, stone setting, and polishing. Each stage requires precision and skill to ensure that the final piece meets the highest standards of quality.

Quality Control: Quality control is an essential part of the custom jewelry making process. Each piece is inspected to ensure that it meets the client's specifications and the jeweler's standards. Any necessary adjustments are made before the piece is delivered to the client.

Final Presentation: The final step in custom jewelry making is the presentation of the finished piece to the client. This moment is special, as the client sees their vision come to life in the form of a beautifully crafted piece of jewelry.

The cost of custom jewelry making varies depending on several factors, including the complexity of the design, the materials used, and the craftsmanship involved. Custom jewelry making prices can range from a few hundred to several thousand dollars. At VELMAR, we provide transparent pricing and work within the client's budget to create a piece that meets their expectations.

Custom jewelry offers several benefits over mass-produced pieces. One of the main advantages is the ability to create a unique piece that reflects the wearer's personality and style. Custom jewelry also allows for greater flexibility in design, as clients can choose specific materials and gemstones. Additionally, custom jewelry is often of higher quality, as each piece is crafted with care and precision.

Custom jewelry is timeless, offering a level of personalization and craftsmanship that mass-produced pieces cannot match. Whether it's a custom engagement ring, a personalized necklace, or a unique bracelet, custom jewelry pieces are cherished for their beauty and individuality. At VELMAR, we take pride in our custom jewelry making process, ensuring that each piece is a true reflection of the client's vision and our craftsmanship.

Custom jewelry making is a journey of creativity, precision, and personal expression. From the initial consultation to the final presentation, each step in the process is carefully executed to create a unique piece of art. At VELMAR, we specialize in custom jewelry making, offering clients the opportunity to own a piece of jewelry that is truly one-of-a-kind. Whether you are looking for handmade jewelry, a custom engagement ring, or a personalized gift, VELMAR is your destination for exceptional custom jewelry.